FW Murphy Production Controls

FW Murphy offers a full line of control panels for a wide range of applications, from engines and motors to pumps and compressors. Simply add your custom design to the instrumentation, layout, and software. You get it exactly how you want it. Murphy's Control Systems & Services division has the experience to provide the correct solution for any control system need, from basic annunciator shutdown panels to complex PLC-based systems.

You know and trust the FW Murphy Production Controls name for your compression needs. Now experience the VRU Pro, dedicated to controlling your system and designed specifically for tank battery vapor recovery compressors. The VRU Pro Controller pairs with single stage reciprocating, screw or scroll compressors and is certified for CSA Class I, Div. 2 hazardous areas, giving you the peace of mind required for your hazardous natural gas applications.

The controller keeps the compressor in a ready-to-start condition until tank pressure reaches a preset level. At that point, it starts the compressor to recover the vapors and draws pressure back down to the set point, when it then turns off the compressor. It’s designed to utilize either AC or DC power. The controller is equipped with 18 fit-for-purpose fixed digital, analog, thermocouple and frequency inputs and nine field-effect transistor (FET) and analog outputs.

Features:

· Full featured Vapor Recovery Unit controller

· Comprehensive signal monitoring and control

· Automatic start and stop based on suction pressure

· Fit for purpose, multifunction I/O including analog inputs / outputs and thermocouple inputs

· Engine / electric motor monitoring and protection features are selectable

· CAN SAE J1939 engine communications with option to adjust speed via TSC1 messages

· Setup configurable through keypad

· CSA C1D2 hazardous-area rated; standard

· MODBUS RTU monitoring and remote control ready (RS-485)

Sales Bulletin - VRU Pro Controller Panel

1611999 2016/09/21

Installation Manual - VRU Pro and WellPro II Controllers

00-02-0956 2015/12/08

Sales Brochure - VRU Pro Controller

1511808 2017/04

TTD is a fully configurable solid-state fault annunciator and shut-down control system designed to protect engines, pumps, compressors and associated equipment. The TTD model accepts 48 sensor inputs from normally open and/or normally closed sensors. Each of the 48 inputs can be configured for shutdown or alarm only. The annunciator provides for both closing of a fuel valve and grounding of an ignition after a time delay.

This easy-to-operate panel features a simple interface. One display head is common to all configurations which requires fewer spare parts. The optional tachometer may use CD ignition or MPU input. The panel offers optional pre-lube or post-lube functionality as well as optional no-flow detection. With the TTD series, the display head is common to all configurations allowing fewer spare parts required to be maintained in the field. Its user-selectable templates provide ease of retrofit by selecting configuration of existing annunciators via display keypad or download from a computer with Windows-based MConfig installed. Any input can be locked out by one of the two start-run timers or configured as Class C, ESD or ignore.

Features:

· Simple interface - Easy to operate

· One display head is common to all configurations requiring fewer spare parts

· Optional tachometer using CD ignition or MPU input

· Optional pre-lube & post-lube functionality

· Optional no-flow detection

· Monitors 48, user-configurable, sensor inputs from N.O. and/or N.C. sensors

· Universal power supplies powered by 12/24VDC or CD ignition (neg. ground)

· CSA Class I, Divisions 1 & 2, Groups B, C, and D

· Internal monitoring of DC Supply, CD ignition, and internal battery voltage

Sales Bulletin - TTD Series

0910435 2016/08/08

Sales Bulletin - TTD Annunciator Panel

0910471 2016/09/09

Installation & Operations Manual - TTD Series

00-02-0697 2016/08/08

Sales Bulletin - TTD Display Head (NEMA)

00-02-0698 2013/03/28

Sales Bulletin - PSU Supplemental

00-02-0694 2009/12/02

The Centurion Configurable Controller is the core of the Centurion control and monitoring system. The latest model, C5-1 puts users in control with diagnostics that reduce troubleshooting, improve communication and enhance data management. Primarily designed for engine/electric motor driven compressors, the Centurion is well suited for many control applications using standard configurations to save money and reduce training. Additionally, FW Murphy specializes in custom designing control packages to meet exact specifications for a variety of applications.

Continuously monitoring input signals, set points and command outputs to maintain proper operation, the Centurion C5-1 controller will stop, shut down or control equipment to change conditions when an out-of-limits event occurs. The auto-start capabilities of the Centurion allow for start/stop based on parameters such as pressure set points or by digital signals. The Centurion provides real-time data via communication ports to a connected display and any remote monitoring system through Ethernet and serial methods.

Features:

· Fully configurable control and monitoring system. Applications include reciprocating/screw compressors and pump systems

· Expandable system to meet most three or four stage compressor applications

· User configurability with Windows-based software allows the operator to point and click to implement standard processes. All I/O points can be custom configured

· No programming experience required

· Local and remote communications, MODBUS RTU via RS485/232/Ethernet

· USB 1.1 / 2.0 support for laptops without a serial port

· Upload/download capabilities for configurations and set points

Sales Bulletin - Centurion C-5 Configurable Controller

1815230 2018/08

Sales Brochure - C5 Get Empowered

1815246 2018/08

Installation Manual - Centurion C5

00-02-0963 2018/08

Modbus Application Guide Map - Centurion C5-1

1815243 2018/08

Important USB Information - Centurion C5

1815242 2018/08

The Centurion PLUS Controller is a custom programmable control and monitoring system. Primarily designed for engine driven compressors, the Centurion PLUS is well suited for many control applications such as CNG control, Fire Pump Control, and many industrial control applications. The panel features custom application programming as well as full-time data logging and expandable communication capabilities. Additionally, a custom control package may be designed to meet exact specifications for a variety of other applications.

The Centurion PLUS continuously monitors input signals and setpoints and commands outputs to maintain proper operation. When an out-of-limits event occurs, the controller will stop, shutdown, or control the equipment to change conditions. The Auto-Start capabilities of the Centurion PLUS allows for start/ stop based on parameters such as pressure setpoints or by digital signals. The Centurion PLUS allows for customer valve logic sequencing, purge cycle control, and many other logic applications. The controller can also provide complex calculation abilities such as rod load and temperature deviation.

The Centurion PLUS system offers multiple options for remote communications and operation including HMI’s, PLC’s, PC’s, and SCADA systems. The industry standard MODBUS RTU protocol means greater support for a wide variety of communication equipment including radio and satellite communications systems. Other communication options include MODBUS TCP/IP, web page hosting, and data logging captured in standard CSV files uploadable through USB port.

Sales Bulletin - Centurion Plus Controller

0910452 2017/12/12

Sales Bulletin - Centurion Plus Control Panel

0910492 2017/12/12

Transfer Guide - Centurion Plus (CPC4-1) Control System

1010537 2012/10/20

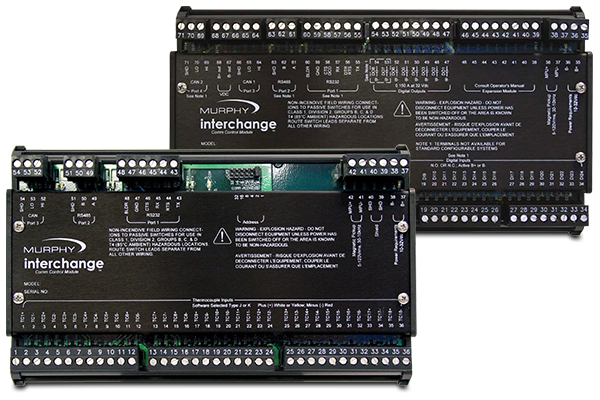

The MX4 expansion module provides temperature and frequency input capability to the C4/CPC4 generation of FW Murphy Controllers using CAN proprietary communication. Serial RS-232 or RS-485 ports also provide other communication methods to work with any MODBUS RTU master device. The MX4 module features 18 thermocouple inputs and 1 magnetic pickup input. Any mix of MX-Series modules can be added to enable Digital and Analog I/O and Temperature inputs for communication and monitoring by the master controller.

The MX4-R2 expansion module provides temperature and frequency input capability to the C5 and future generations of FW Murphy Controllers using CAN proprietary communication with enhanced diagnostics. Serial RS-485 port and 2 Ethernet ports also provide other communication methods to work with any MODBUS RTU or MODBUS TCP/IP master device. The MX4-R2 module features 18 thermocouple / 9 RTD inputs and 1 magnetic pickup input. MX4-R2 is backward compatible to MX4.

The MX5 expansion module provides input/output capability to the C4/CPC4 generation of FW Murphy Controllers using CAN proprietary communications. Serial RS-232 or RS-485 ports also provide other communication methods to work with any MODBUS RTU master device. The base MX5 module features 24 Digital inputs, 8 Digital outputs, 10 Analog inputs, and 1 magnetic pickup input. The MX5-A model provides an additional 4 Analog outputs to the base MX5. The MX5-D model offers an additional 8 Digital outputs to the base MX5.

The MX5-R2 expansion module provides input/output capability to the C5 generation and future generations of FW Murphy Controllers using CAN proprietary communications with enhanced diagnostics. Serial RS-232 or RS-485 ports and 2 Ethernet ports also provide other communication methods to work with any MODBUS RTU or MODBUS TCP/IP master device. The MX5-R2 module features 24 Digital inputs, 16 Digital outputs, 10 Analog inputs, 4 Analog outputs, and 1 magnetic pickup input. MX5-R2 is backward compatible all models of the MX5.

Installation & Operations Manual - MX4 Series

00-02-0695 2011/12/06

Installation & Operations Manual - MX5 Series

00-02-0628 2013/03/07

The LCDT Selectronic Tattletale system is a compact fault annunciator with an electronic alarm/shutdown control system. It’s designed to protect engine-driven or motor-driven compressors and pumps. The annunciator indicates the sensor, and hence the parameter, that causes an alarm or shutdown. In addition, a means is provided for testing the operation of each sensor without initiating an alarm or shutdown.

At the heart of the system, the basic annunciator component has two variations: the Model LCDT-NO, which accommodates normally open sensors; and the Model LCDT-NC, which accommodates normally closed sensors. These units are enclosed in an aluminum box having a brush finish. The LCDT system accommodates 47 NO or 45 NC sensor inputs, 15 of which may be locked out during start up by the start/run timer delay.

Employing a liquid crystal display, the LCDT system gives a digital reading of the tripped sensor and the lockout timer countdown. A separate power supply is provided with the model LCDT instrument. Power may be supplied by CD ignition, a 120 VAC line or by 12- or 24-VDC battery. Intended for use with all Swichgage instruments without OS option.

Sales Bulletin - LCDT Selectronic Tattletale System

8535 2014/12/05

Installation & Operations Manual - LCDT Selectronic Tattletale Instrument

00-02-0205 2006/07

Diagram - LCDT N.O. Installation: HC9450-A

HC9450-A 1986/09/18

Diagram - LCDT N.C. Installation: HD9450-AA

HD9450-AA 1986/09/18

The S1501 instrument is a microprocessor-based alarm, shutdown and control system with tachometer/hourmeter function. It annunciates in alphanumeric characters the protective device that has signaled an alarm or caused equipment shutdown. Information is called up and adjustments are made on a six-button keypad on the face of the unit. Configurations such as alarm or shut-down nomenclature, preset timers and tachometer calibration can be made in the field.

The complete S1501 system consists of a head, sensor input terminal strip (two needed for 64 sensor models), 36-inch (914 mm) flat ribbon cable(s) for connecting the terminal block to the head and a Class I, Div. 1, explosion-proof power supply. The S1501 system is powered from 120 VAC or 12 or 24 VDC. The head is rated intrinsically safe and includes a communication port, jumper selectable for either RS232 or RS485, operating as a MODBUS RTU slave. This port allows for remote control functions such as start/stop, load/unload, etc., and for read access to S1501 holding registers.

The FW Murphy S1501 system has seven SPDT relays. On the standard model, the relays are assigned to the following functions: lube, crank, ignition/motor, fuel valve/cooler, load, alarm and shutdown. The S1501 system can be configured to monitor applications such as air and natural gas compressors, natural gas refueling and other industrial operations. MConfig™ Software can be used to download to or upload from the S1501 and to save configurations.

Sales Bulletin - Series S1501 Selectronic Microcontroller

96122 2014/12/05

Installation & Operations Manual - Series S1501 Selectronic Microcontroller

00-02-0819 2011/12/21

Installation & Operations Manual - Series S1501 Selectronic Microcontroller

00-02-0271 2009/06/16

Installation Diagram - Series S1501

50-08-0017 1997/04/01

With more than 75 years of history, Murphy’s Control Systems & Services division has the experience to provide the correct solution for any control system need. Murphy works with clients to quickly identify critical needs and cost-effective solutions in a wide variety of control systems applications, from basic annunciator shut-down panels to complex PLC-based systems.

CS&S takes any project from conception to completion and beyond with 24-hour technical support.

Services include:

· Project Management

· Design and Engineering

· Testing

· Training

· Technical Support

Project Management: Dedicated to the Details

FW Murphy Production Controls employees have the proven ability to take your project from concept to design to fabrication and field support. They begin the process with the end in mind, utilizing a consultative approach to get a clear picture of your desired end result.

Design and Engineering: Built Right, Every Time

Consistent design maintains similar look and feel across many different PLC panels. This concept allows production, support staff, customer staff and end users to be familiar with the control panel even before they see it for the first time.

Start-Up Assistance: Money Saved, Not Spent

In the oil and gas industry, start ups are critical. Having the right personnel on site can save downtime and money by reducing lost production time. Downtime is expensive and can be minimized by having a PLC Service Engineer provide the technical expertise needed for advanced troubleshooting and on-site control philosophy modifications.

Troubleshooting: Extensive Knowledge When & Where You Need It

Equipment malfunctions can happen any time, day or night. Murphy provides 24-hour technical support to help get your equipment back up and running. Their support team is available by phone to answer your questions and assist with troubleshooting.

Training: Helping Your Team

Murphy's dedicated team of PLC Engineers help your operators feel more comfortable with the systems by spending time with them to go through the PLC as well as provide basic troubleshooting tips.

Sales Bulletin - Control Systems & Services

1210950 2015/10/01

Sales Flier - Control Systems & Services

1210975 2017/04