Beaumont Manufacturing & Distribution

Beaumont Manufacturing and Distribution Company, LLC (BMD) was formed in August of 2015 to manufacture high quality control equipment for the upstream oil and gas industry. Our company mission is to:

· Deliver the highest value the industry has to offer at the lowest cost to the customer.

· Develop lasting customer relationships through exceptional customer service.

· Propel the industry forward by innovating new and creative solutions.

· Provide stability in an unpredictable and changing marketplace.

To achieve these goals BMD has dedicated itself to several core principles: honesty, integrity, quality, innovation, and value delivery through lean manufacturing and exceeding customer expectations.

Our expanding product offering currently includes: control valves, level controllers and switches, pressure controllers, regulators and relief valves that come in a wide variety of sizes, end connections and material combinations to fit the customers' specific needs.

The CV10 is a close coupled control valve also known as a dump valve. It’s ideally suited for a wide range of applications such as pressure control, level control and flow control. Typical installations include separators, scrubbers, wellheads and other production equipment. The CV10’s hammer union makes maintenance easy by allowing the topworks to be removed without taking the valve out of line. This feature reduces the amount of time needed to inspect and replace the valve trim. The CV10 is available in a variety of material options and different trim sizes. A NACE option is also available for sour service.

CV10 Control Valve Brochure (pdf)

The CV20 is a rugged, compact, freezeless dump valve. The body can be installed so that the valve cage and plug are submerged into the process media giving the valve its freezeless characteristic. Typical installations include separators, scrubbers, and other production vessels. The CV20’s hammer union makes maintenance easy by allowing the topworks to be removed without taking the valve out of line. This makes it easy to inspect and replace the valve trim. Using the same trim set as the CV10 valve, the CV20 offers the versatility of multiple trim sizes and material options. A NACE option is also available for sour service.

CV20 Control Valve Brochure (pdf)

The CV25 is a compact, economical dump valve solution. It consists of a freezeless angle body design coupled with a low profile actuator. The plug and seat are both submerged in the process media to give the valve its freezeless characteristic. Typical installations include separators, compressor skids, and other production equipment. The CV25 is available with a metal to metal or soft seat option, and a NACE option is available for sour service.

CV25 Control Valve Brochure (pdf)

The LC10 is a rugged, displacer operated liquid level controller that is ideal for use on scrubbers, separators, heater treaters or anywhere else liquid level control is needed. Its industry-proven force balance design allows for control of gas/liquid as well as liquid/liquid interfaces. The LC10 can be mounted on the left or right hand side and can be set up for direct or reverse acting. Both the mounting and action are field reversible. Its available with an easily replaceable snap or throttling pilot for pneumatic control. The snap pilot is available with a soft seat option that meets 40 CFR Part 60, Subpart 0000.* SPDT and DPDT switches are available for electric control. A wide variety of sizes and end connections are available, as well as many different displacer arm lengths to fit any vessel configuration. A NACE option is also available for sour service.

LC10 Level Controller Brochure (pdf)

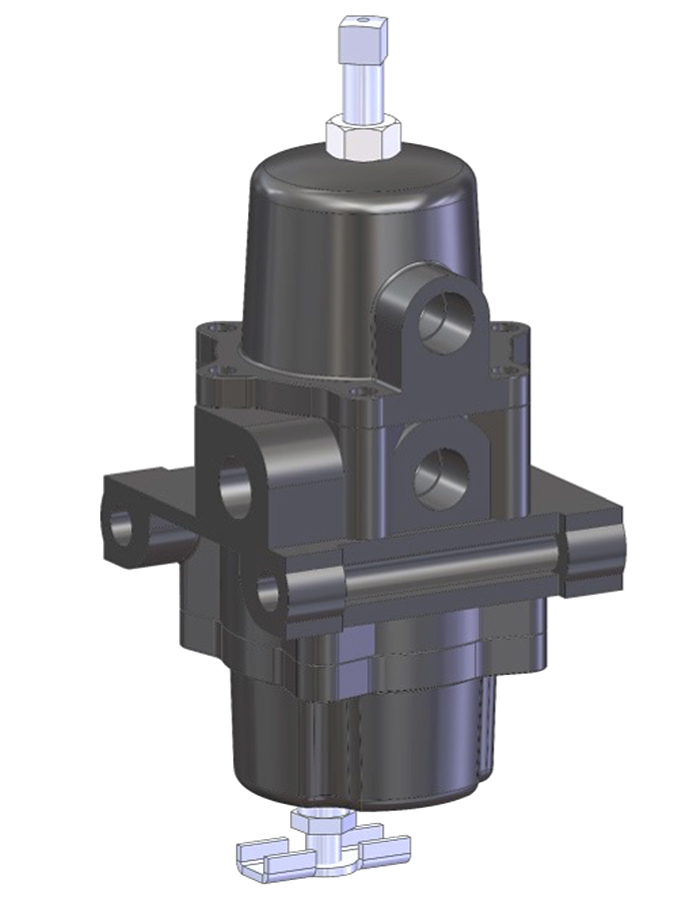

The RG10 is a high pressure, direct spring operated, pressure regulator. Its high pressure, heavy duty design makes it ideal for pressure regulation in the oil and natural gas industry. Typical applications include farm taps, first or second cut regulation, transmission to distribution and many other high pressure processes. It has a maximum inlet pressure of 1500 psi and an outlet range of 27-500 psi. The RG10 also has the ability to be converted into a relief valve. A NACE option is available for sour service.

RG10 Regulator Brochure (pdf)

The RG20 is a direct spring operated, pressure regulator that can be used anywhere pressure regulation of natural gas, air or other gas is required. Its housing can be moved to one of four positions to save space during installation.

The RG20 was designed for easy maintenance by allowing access to the body without removing it from the line. A NACE option is available for sour service.

RG20 Regulator Brochure (pdf)

The RG30 is a compact, spring-operated regulator normally used to supply air or gas to pilots, positioners or other pneumatic controls.

It features an internal relief to help maintain an accurate downstream pressure, rugged aluminum housing construction with dual outlets and a built-in micron filter.

RG30 Regulator Brochure (pdf)

The RG40 is a compact, high pressure, spring operated regulator designed to reduce high pressures down to working pressures. It features a rugged brass body and housing with a durable metal diaphragm and nylon disk for handling high pressure drops.

Typical applications include reduction of high pressure to operate chemical injection pumps, valve actuators or controllers. Its compact form and cost effective design make it an ideal choice for many other applications as well.

RG40 Regulator Brochure (pdf)

The RV10 safety relief valve is well-suited for overpressure protection of production equipment, including compressors, scrubbers, separators, pipelines or anywhere overpressure protection may be required. The RV10 design incorporates a non-rising stem to give the disk full guidance while opening and closing. The non-rising stem coupled with the valve’s soft-seat design ensures long lasting set pressure repeatability and bubble-tight shutoff.

The shorter stem also makes the valve more compact, making it ideal for requirements where space may be an issue. The RV10 is ASME certified for gas service and is available in NPT and flanged connections. Flanged sizes meet API 526 dimensions. The RV10 series covers set pressure ranges from 15 – 3000 psi (103-20684 kPa) with orifice sizes ranging from D to M. Orifice sizes exceed API minimum areas for increased flow rates.

The RV10 is manufactured in accordance with the ASME Boiler and Pressure Vessel Code, capacity tested and certified by the National Board, and meet the requirements of Sec on VIII, Division 1 of the ASME Code.

RV10 Relief Valve Brochure (pdf)