TDI T30-M Lube Oil Pump Motor

Your engine and equipment life depends on reliable oil lubrication, before, during and after operation. Cold starts, or worse, dry starts take a heavy toll on engine and equipment bearings, contributing hundreds of extra hours of wear at every start. Once running, hot engine shut downs can scorch oil and ruin turbocharger bearings. Since budgets demand fuel savings, simply leaving your equipment running is not cost effective. You need a reliable pre-lubrication and post-lubrication system to protect your engine and equipment from hours of unnecessary wear at every start and every shut down. And no pneumatic motor driven oil pump is more reliable than TDI's TurboTwin T30-M.

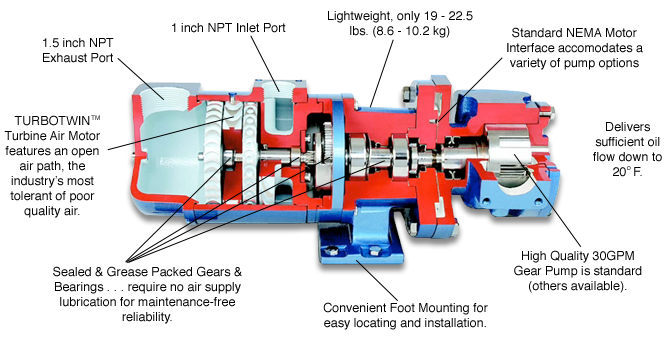

Vane-type air motors are not designed for the kind of service required by an equipment lube system. While gear-type oil pumps deliver years of dependable service, vane-type air motors are quickly destroyed by harsh conditions such as air system moisture, contamination and lack of lubrication (depleted air line lubricators). Sensitive pneumatic diaphragm-type oil pumps can be even less durable in these conditions. TurboTwin motors are different. Rust, scale and even heavy moisture flow right through TurboTwin’s open air path design with little effect. TurboTwin runs cool because there are no cylinders or rubbing vanes to heat up wear out, or break down. TDI TurboTwin T30-M turbine air motors are flat out the most durable you can buy. They are especially reliable in harsh operating conditions.

One key to the reliability of the T30-M is that they simply do not require air line lubricators, regardless of the quality of the air/gas supply. You’ll spend less for coalescing filters, dryers and air treatment. No oily mist in the motor exhaust means a TurboTwin motor runs cleaner. At oil pump output speeds from 1000- 1800 RPM, lubrication cycles that are ten, twenty, even thirty minutes in duration, will not overheat a TurboTwin. Exhaust gas from the turbine actually cools bearings and the gearbox, without oil gumming or motor freeze-ups.

The T30-M efficiently delivers dependable, consistent power at about half the operating pressure required by vane-type motors. Anywhere you have equipment, oil can be quickly circulated everywhere it is needed. What could be better than a powerful air motor that runs clean, cool and for a very long time, letting your lube system protect your equipment.

T30-M motors driven lube pumps are flexibly packaged. Standard mounts and interfaces provide easy installation. The three basic configurations are:

· Foot-mounted T30-M Air/Gas motor with standard NEMA interface

· Foot-mounted Air/Gas Motor with a top quality 30GPM gear-type oil pump

· Complete “Plug & Play” package (all of the above plus specified motor controls – air only)

Specifications

· Air Motor Type: Turbine

· Gear ratio: 9:1

· Rotation: CW or CCW

· Motor (only) Supply: Compressed air or natural gas

· Motor Inlet: 1 inch NPT-F

· Motor Exhaust: 1.5" NPT-F Elbow

· Output: 5 hp @ 1750 rpm, 130 SCFM air flow @ 60 psig

· Output: 5.5 hp @ 1750 rpm, 160 SCFM methane gas flow @ 60 psig

· Max Motor Operating Pressure: 40-60 psig (w/30GPM pump load)

· Max Recommended Output: Motor rpm - 2250 rpm

· Recommended Duty Cycle: Intermittent Only: 1-30 minutes max.

Literature

· See detailed specifications on the TurboValve Plus sales bulletin , available on the TDI literature page.