CPI Compressor Valves

It is widely acknowledged that the compressor valve is the heart of any compressor; the efficient and reliable operation of this most critical part of a reciprocating compressor is key to its overall performance.

Valve problems are reportedly the primary reason for reciprocating compressor shutdowns, which in many cases can be attributed to design, improper reconditioning or external operating factors. CPI compressor valves are custom designed to meet the full range of application requirements. These designs include concentric ring, ported plate, poppet, and channel type. Suction and discharge valves can be supplied to include CPI’s Indicator Ported Valve design. CPI valves can also be fitted with a range of plug and finger unloaders and actuators.

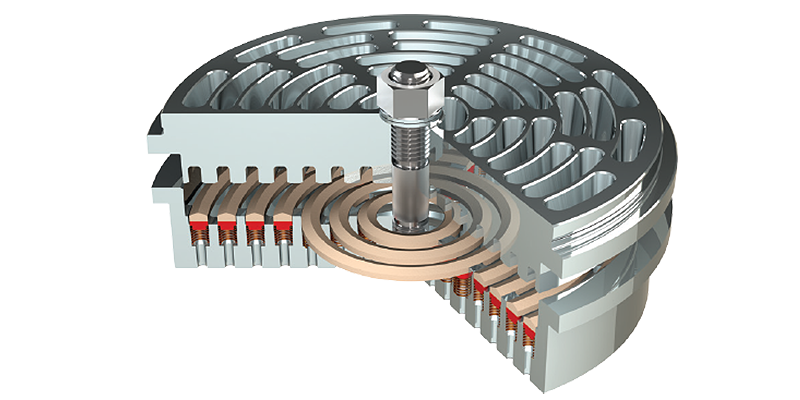

The CPI Hi-Flo VP compressor valve is a high performance valve that takes advantage of a unique sealing element profile. This aerodynamic profile provides:

· Minimum resistance to flow

· Lower pressure drop across valve

· Improved reliability in services with liquids and debris in the gas stream virtually eliminating any foreign

Flat ring designs result in a greater pressure drop because the gas flow through such valves must deflect 90° at two locations to pass around the ring or plate. The Hi-Flo VP and DP design eliminates these drastic changes in direction and efficiently directs the flow of the gas through the valve.

The aerodynamic Hi-Flo design reduces valve pressure drop by providing a low resistance to gas flow. Improved compressor performance can be realized since valve power losses and valve capacity losses are directly related to valve pressure drop.

The Hi-Flo valves perform extremely well under the dirty gas and liquid slug conditions where flat ring valves typically fail. The aerodynamic angle of the Hi-Flo sealing element deflects any debris or liquid that may be present in the gas stream, virtually eliminating any build-up on the sealing surfaces.

Ring Material: Nylon

Recommended RPM Range: <1800 rpm

Maximum Operating Temperature: 225°F / 107°C

Ring Material: PEEK

Recommended RPM Range: <1800 rpm

Maximum Operating Temperature: 425°F / 218°C

Hi-Flo Advantages:

· Good performance with liquids or dirty service.

· Aerodynamic flow results in lower pressure drop.

· Available with finger or plug-type unloaders.

Sales Bulletin: Hi-Flo VP Valves

(HIFLOVP1608.LTR)

Sales Bulletin: Compressor Services

(CS.1506.LTR)

Overview Bulletin: Compressor Valves

(VALVEOVERVIEW.1803.LTR)

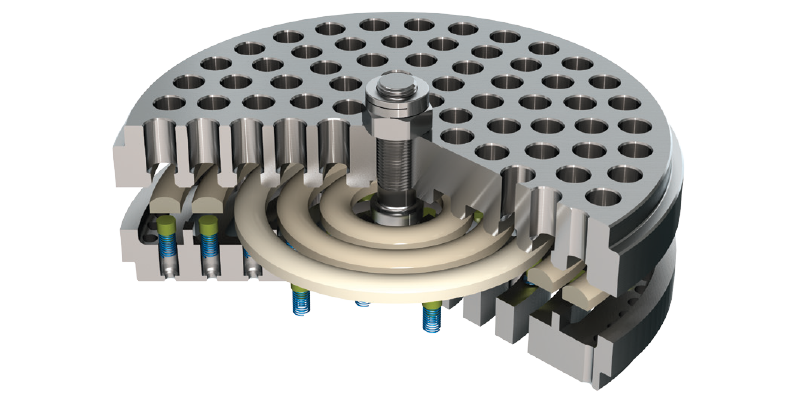

CPI's Hi-Flo compressor valves are reliable in the oil, gas, petrochemical and air separation industries globally. The CPI Hi-Flo RD valve is capable of operating across a wide range of parameters, including discharge temperatures in excess of 200°C / 390°F and pressures in excess of 400 bar / 6000psi. CPI radiused profile valves are also suitable for sour gas applications.

Each valve is individually designed to match the compressor operating conditions for the application. To achieve this, close cooperation with the operator or compressor manufacturer is involved, including a full review of operating and dimensional data to ensure complete interchangeability with existing valves.

The unique radiused profile of the valve discs, which control and seal the process gas as it flows into and from the compressor cylinder, provides a number of important characteristics.

With radiused discs and matching radii on the seat, discs and seats become self-aligning ensuring good conformability throughout the variation of operating temperatures. Effective sealing between disc and seat is continually maintained resulting in efficient flow.

· Reliable performance in the most demanding operating conditions

· Provides increased operational efficiency and reduced power consumption

· Offers improved flow and reduced pressure drop and back flow

· Easily maintained and reconditioned

· Nose diameter – 2.375 inch / 60 mm and up

· Capable of operating across a wide range of parameters, including:

◦ temperatures up to 390°F / 200°C

◦ pressures up to 6000 psi / 400 bar

· Delivers self-aligning performance with good conformability and effective sealing throughout changing temperatures during operating cycles

· Custom spring design for each application to optimize opening and closing time

· Available with finger and plug-type unloaders

· Suitable for:

◦ both lubricated and non-lubricated compressors

◦ sour gas applications

◦ compressor speed up to 1800 RPM

All materials of the seat, guard, springs and other internal components are heat treated within the hardness ranges specified by NACE, as the most desirable to resist sulphide stress cracking in H2S - rich gases. This is made possible due to the low impact loads and wear imparted by the thermoplastic discs, in contrast to metal-plate valves, many of which use hardened plates and seats for wear resistance.

Sales Bulletin: Hi-Flo RD Valves

(HIFLORD.1801.LTR)

Sales Bulletin: Compressor Services

(CS.1506.LTR)

Overview Bulletin: Compressor Valves

(VALVEOVERVIEW.1803.LTR)

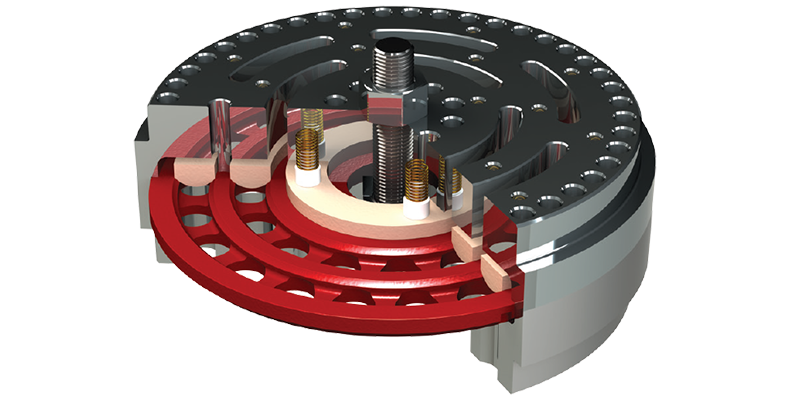

The CPI Engineering Department has produced a design which incorporates a replaceable metal or peek seat plate within the existing radiused disc valve. This concept can also be applied to CPI Hi-Flo valves and easily used at compressor operations for maintenance.This concept was conceived to satisfy specific customer demands who were successfully operating compressors using CPI radiused disc valves installed in off shore production platforms, FPSOs and facilities where no maintenance workshops are available.

The remoteness of compressors in these operating environments, the need for specialist skills and equipment to overhaul them in remote operations or when reconditioning was necessary were no longer issues when operators used the Replaceable Seat Plate Valve.

· CPI valve reconditioning can be carried out on the platform or FPSO.

· No special tools, presses or equipment are necessary.

· No re-machining is necessary.

· No reduction in valve seat thickness, consequently on suction valve reconditioning, no adjustment is necessary if unloader forks are fitted.

· No spare valve inventory is necessary.

Sales Bulletin: Hi-Flo RS Valves

(HIFLORS.1803.LTR)

Sales Bulletin: Compressor Services

(CS.1506.LTR)

Overview Bulletin: Compressor Valves

(VALVEOVERVIEW.1803.LTR)

CPI designs valve solutions for operators in refinery, petro chemical, process, gas lift, gas injection and industrial air industries. CPI compression engineers utilize sophisticated proprietary valve dynamics programs to carry out valve performance modeling and analysis of existing operations, in order to accurately select the optimum valve design solution for a specific application. This is combined with R&D programs that are focused on all aspects of valve design detail, materials, reliability, efficiency, ease of installation and maintenance.

CPI ring type valves are manufactured to the highest quality, using either metallic and non-metallic ring components for compressors operating in a range of differing applications, both lubricated and non-lubricated. Achieving the optimum performance and reliability are key to most operators and CPI ring valves can deliver across the broad spectrum of applications and operating conditions required.

· Hi-Flo

· Radiused Disc

· The valve dynamics of geometry optimizes flow and efficiency in operation.

· Seats and guards manufactured from a variety of metallic materials suitable for a broad range of applications.

· Integral guides are incorporated into guard design, enabling effective ring sealing.

· CPI materials technology employed into nonmetallic ring components.

· Non-metallic materials provide excellent chemical resistance, high temperature tolerances and strong impact capabilities, in a wide variety of applications.

· Springs and button materials specifically selected for efficient performance in specific applications.

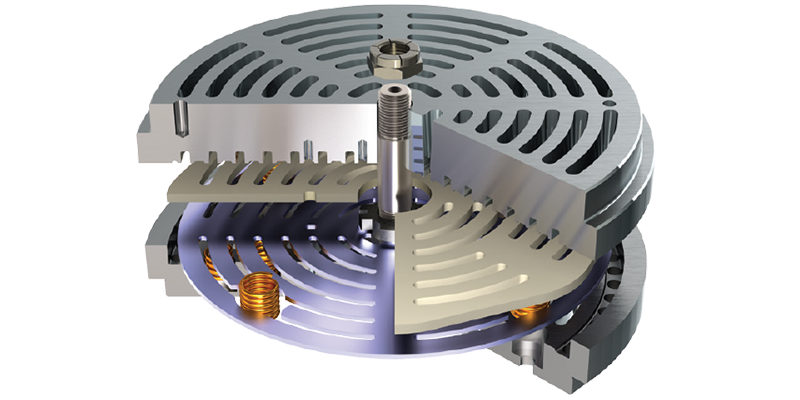

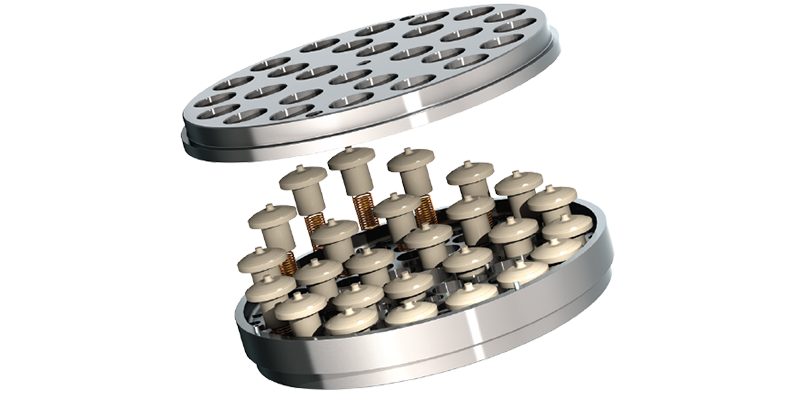

CPI ported plate valves provide operators with a comprehensive range of both metallic and non-metallic plate valve assemblies and internal components, manufactured to the highest quality, for air and process gas compressors operating in a range of different applications. Achieving the optimum performance and reliability are key to most operators and CPI ported plate valves can deliver across the broad spectrum of applications and operating conditions required.

Metallic sealing and dampening discs are manufactured using high quality stainless steel, which is heat treated and tempered to the appropriate hardness, to provide an economical material with excellent performance for a broad range of applications. CPI materials technology is an integral part of the non-metallic sealing and dampening discs manufactured for CPI plate valves. Due to the properties of non-metallic materials, plate, disc and other internal components incorporated into CPI ported plate valves, are specifically selected to reliably perform in the operating conditions and gas properties of a particular application.

· Seats and guards manufactured from a variety of metallic materials suitable for a broad range of applications.

· Integral guides are incorporated into the guard design, enabling effective ring sealing.

· CPI materials technology utilized to create non-metallic ring components.

· Non-metallic materials provide excellent chemical resistance, high temperature tolerances and strong impact capabilities, in a wide variety of applications.

· Springs and button materials are specifically selected for efficient performance in specific applications.

Sales Bulletin: Ported Plate Valves

(PPV.1608.LTR)

For lubricated, high speed service, our damped disc-type valves provide excellent performance. These valves employ two additional spring-loaded discs which effectively reduce flutter and cushion the impact of opening and closing.

The built-in dampening action of these valves makes them particularly suitable for compressors operating at high speeds (750 rpm or more), and in applications with either a high pressure differential (greater than 250 psi or 17 atm differential) or varying pressure conditions within the same compressor. The cushioning action of our dampened disc-type valves is effective in overcoming inertial forces in high speed compressors. Our damped disc-type valves employ a guide ring which serves as the central bearing element. It can be easily and inexpensively replaced when wear inevitably occurs.

The fully-machined seat and guard are offered in Type 4140 AQ steel as standard, and Types 416 or 303 stainless steel for more corrosive service. The replaceable guide ring is normally furnished in the same material as the seat and guard.

The valve disc and dampening discs can be furnished in stainless steel, or any of our non-metallic disc materials.

Poppet valves are precision machined for your application and are available in single deck, deck-and-a-half, and double deck valve configurations. CPI poppet valves are adaptable to existing plug style unloaders, or can be supplied with new plug unloader systems. Finger unloaders are also available for poppet valves with smaller nose diameters. The large seat and guard porting result in a valve that can be used effectively in applications in which debris or liquid is present. The poppet itself is designed to withstand high pressure differentials and high impact velocities, while providing a smooth, aerodynamic flow surface. Along with the large porting in the seat and guard, the poppets contribute to a low valve pressure drop, which results in lower valve loss power, lower valve temperature increase, and improved capacity. All CPI poppets are injected molded in-house to ensure complete quality control from raw material to finished product.

Since the CPI poppet is designed to perform well in a wide range of services, only a single poppet design is necessary for all CPI poppet valves. Also since CPI sets valve lift by varying the fully machined guard geometry, only one poppet design is required to achieve any lift. The use of a single poppet design results in reduced customer inventory.

CPI poppet valves permit the easiest and most economical reconditioning when required. Seats can be fully reconditioned by the customer on-site utilizing our readily available reconditioning tools, or at one of our conveniently located service centers. Poppets and springs are easy to stock and are also readily available from CPI.

Ring Material: Nylon

Recommended RPM Range: <1000 rpm

Maximum Operating Temperature: 225°F / 107°C

Ring Material: PEEK

Recommended RPM Range: <1000 rpm

Maximum Operating Temperature: 425°F / 218°C

Poppet Advantages:

· Low Pressure drop due to high free lift area (Reduced valve HP loss).

· Standardization of poppet design requires less replacement parts inventory.

· No maximum limit on valve outside diameter.

· High lift can pass debris.

· Can continue to run with damaged/missing poppets.

Sales Bulletin: Poppet Valves

(POPPET.1608.LTR)

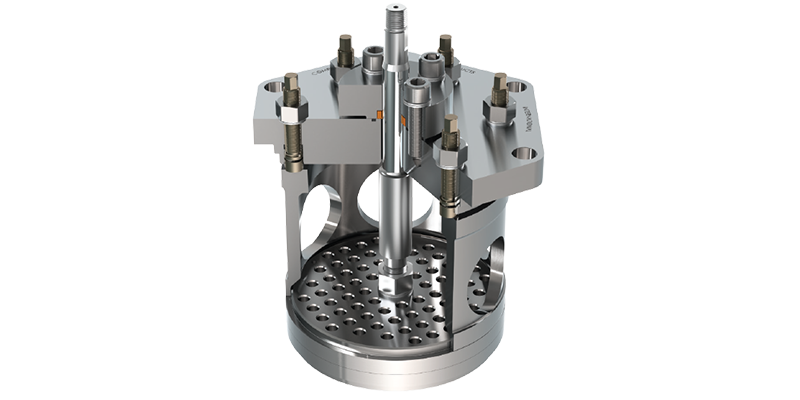

The CPI Indicator Ported Valve (IPV) allows performance analysis of compressor cylinders that do not have tapped indicator ports. The IPV does this by providing a connection to the internal cylinder pressure through the center of the valve stud. An indicator valve is then mounted on the end of the IPV for connecting an external pressure transducer. This allows cylinders that previously were not able to be monitored to be analyzed after a standard valve change out.

The CPI IPV is available with any new CPI valve including Hi-Flo, RD valve, ring, poppet, or plate style or can be retrofitted to existing valves. Only one IPV is required per active cylinder end and they can be designed for either suction or discharge valves. They can also be incorporated into valve, cover, jack bolt, and gasket upgrade projects.

· The CPI IPV fits existing valve ports eliminating expensive cylinder disassembly, machining and hydro testing.

· Provides access to the internal cylinder pressure to monitor part performance and horsepower.

· Routine diagnostic testing with the CPI IPV enhances reliability to extend mean time between failures.

Sales Bulletin: Indicator Ported Valves

(IPV.1608.LTR)

CPI molds engineered plastic materials used in the reciprocating compressor industry. These materials include Nylon, PEEK and other proprietary blends. Blank sizes are held to close tolerances and pass several quality checks to exceed customer requirements. Over one hundred different blank sizes are currently available.

Today's advanced polymers have excellent mechanical properties and are capable of working at temperatures up to 400+ degrees F. In most cases, a simple conversion to low mass polymer sealing elements can give existing valves in reciprocating compressors a vastly increased life as well as reduced energy consumption and maintenance costs, without having to alter the valve body or modify the valve cage.

The main advantages of polymer plates & rings over metallic are as follows:

· Manufactured to exact size

· High stock availability

· One source for all your Peek, Nylon & Mid-Temperature valve plates

· Glass Filled Peek, Carbon Filled Peek

· Glass Filled Natural & Yellow Nylon

· Glass Filled Mid-Temperature Material