End Devices

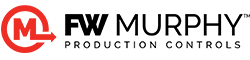

The AT03069 is a completely reliable heavy-duty device developed specifically to automatically control engine speed to meet system demand. Low current, high torque, solid-state switching and an electronic clutch make it ideal for all automatic and semiautomatic engine systems.

Used with the appropriate Murphy Swichgage near constant pressure, level and load can be maintained. Speed changes are made slowly and smoothly. The device saves fuel, engine wear, horsepower and labor. One model can be used with both 12- and 24-VDC systems. Check with our engineers for help with other applications where speed control can improve your system.

The AT03069 can enhance features of our Selectronic Microcontroller units by allowing features such as:

· Warm-up RPM set point

· Minimum RPM set point

· Maximum RPM set point

· Preset operating RPM set point

· Auto throttling to match flows (as needed in flood control applications)

· Maintaining system pressure (as needed in booster station application)

· Adjustable rate of change in RPM (allowing fine tuning of overall system)

Sales Bulletin: AT03069

00-02-0568 rev. 2016/03/11

Instruction Supplement: AT03069

AT03069-I rev. 2004/02

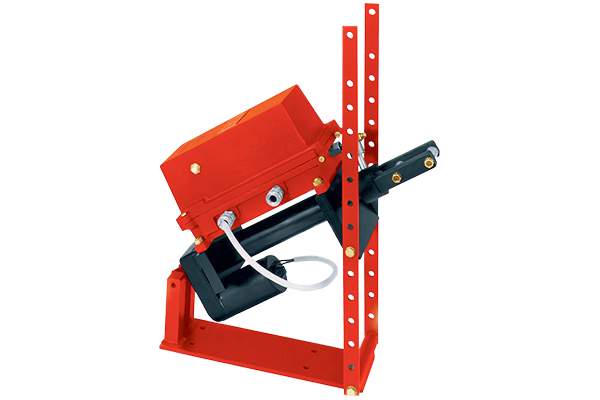

The CO3 is an electrically controlled and driven actuator for automatic operation of two position, lever action equipment. Primarily designed to engage and disengage over-center clutches on engines, the CO3 has a wide variety of applications such as opening and closing of pipeline valves, engagement and disengagement of pumps, fixture positioning in automated process control, etc.

The positive action screw-type actuator is fully adjustable for length of stroke up to 6 inches (152 mm). The CO3 motor is equipped with an overload clutch that slips if overloaded. In addition, the motor is protected with an automatic reset thermal overload. The CO3 is available for 12- or 24-VDC applications and is compatible with Murphymatic start-stop engine controllers.

Applications include:

· Engine disc clutches

· Butterfly and ball valves

· Brakes

· Two position lever-action equipment

Sales Bulletin/Installation Instructions: CO3

01035 rev. 2014/10/22

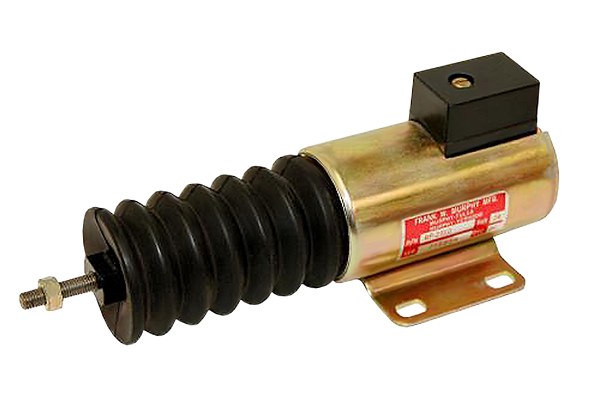

The Murphy Push/Pull DC Solenoids provide single unit versatility for engine applications, such as shutdown. One solenoid offers pull/push operation. The RP Series has no internal switches, reduces coil burnout and reduces adjustments while boosting reliability. The solenoid offers high force in its small size. It can be used with most engines’ start systems.

A choice of two models and two voltages is available. All models come complete with return spring and rubber seal boot. An SD85 Solenoid Drive Time Delay is also available to greatly reduce possibility of coil burnout and to facilitate low current-piloted operation.

Models RP2307B and RP2308B give a full 1 in. (25 mm) stroke at 11 pounds (49 N) and hold up to 27 pounds (120 N) at full voltage, continuous duty. They will operate at any stroke less than maximum.

Models RP2309B and RP2310B can pull 17 pounds (75 N) with a 1-1/2 in. (38 mm) stroke. They hold up to 35 pounds (155 N) at full voltage, continuous duty. See the sales bulletin for holding force at any stroke less than maximum.

Sales Bulletin/Installation Instructions: RP Series

00-02-0107 rev. 2017/07/19

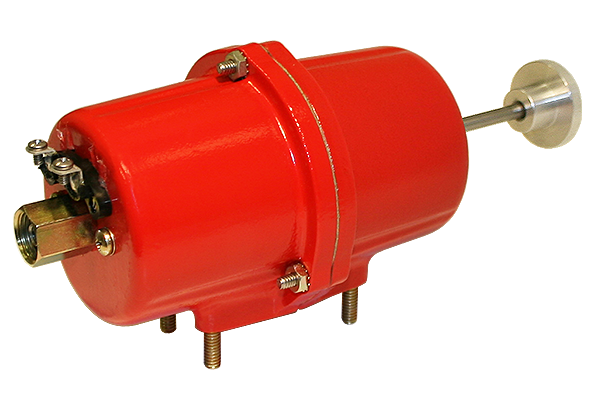

The RP75 Rack Puller is a semiautomatic device that provides a pulling force to initiate shut down of diesel engines and equipment. The RP75 connects to the injection pump or air intake shut-off lever via a cable (chain optional). A coil spring, within the RP75, is reset manually and is held in place by an electromagnet.

When the Swichgage detects a malfunction, the electromagnetic circuit is interrupted through a magnetic switch — releasing the coil spring thus pulling the cable/chain to actuate shutdown. When fully compressed, the spring exerts a pull of 30 lbf (133 N).

The RP75 is available for 12- or 24-VDC applications and is compatible with all Swichgage instruments.

Sales Bulletin/Installation Instructions: Model RP75

95028 rev. 2014/10/20