End Devices

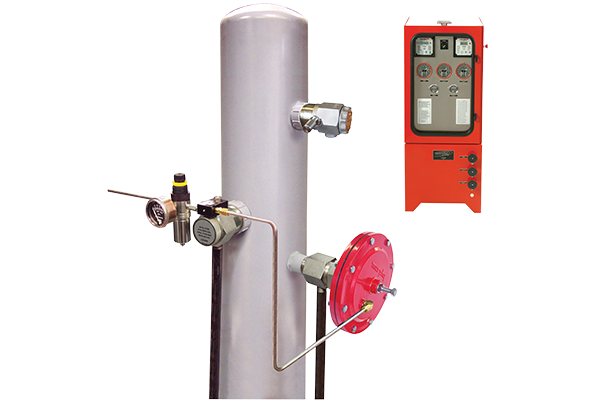

The LM500 maintains oil level on any size engine. It also supports installations that require a three-wire, snap-action switch. The form C (three-wire) contact allows a controller/annunciator to be wired as a closed-loop system, resulting in a reliable fault-sensitive circuit. The Murphy LM500-TF Oil Level Maintainer includes a test feature that confirms both the float and switch are operating correctly with a single press of the test button.

The LM500 series maintains the crankcase oil level of an engine, pump or compressor. Adjusted to the correct running oil level, it will replenish oil as it is used. The low-level switch will alarm and/or shut-down the equipment, if supply oil is lost and the equipment continues to use oil.

As crankcase oil level drops, the LM500 float also drops and opens the Thumb-Valve. This allows oil to flow from the supply tank through the LM500 and into the crankcase. When proper level is achieved in the crankcase, the LM500 float rises causing the Thumb-Valve to close off further oil flow.

The simple and unique Thumb-Valve is non-clogging and provides a positive, leak-free seal. If the clean oil supply is depleted and oil level continues to fall, the low-level switch will operate an alarm or equipment shutdown.

Sales Bulletin: LM500/LM500-TF

1010627 rev. 2015/11/30

Sales Bulletin: LM500-TF-ATEX

1010684 rev. 2013/09/13

Installation Instructions: LM500/LM500-TF

00-02-0729 rev. 2015/05/30

Installation Instructions: LM500-TF-ATEX

00-02-0745 rev. 2013/09/16

Bubble Lens Assembly Instruction: LM500/LM500-TF

00-02-0785 rev. 2011/11/02

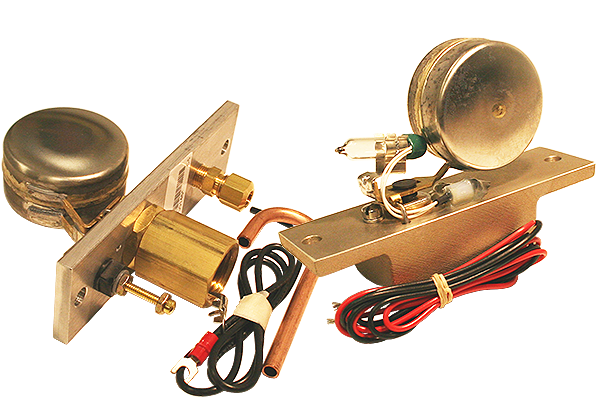

The LM300 Series Level Maintainer automatically adds oil to the crankcase as needed to keep the lube level normal. Most models have built-in switches that will alarm and/or shut down the equipment if the makeup supply is depleted and engine oil level falls or if overfill conditions exist. The LM300 can be used in engines, compressors, pumps and coolers.

The LM300 Series EX models (explosion-proof) are CSA certified for Class I, Division 1 Hazardous areas.

Sales Bulletin: LM300 Series

92149 rev. 2016/11/16

Installation Instructions: LM300 Series

00-02-0176 rev. 2016/11/16

Glass Lens Kit Installation: LM300

00-02-0905 rev. 2016/06/23

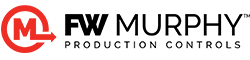

The system provides for liquid control in gas scrubber applications by dumping liquids to drain and protect compressors with with high liquid level switch. Wetted metal parts are made to survive constant use in corrosive environments.

You save money by purchasing the SLS system which includes the following:

· LS200, MLS-020 High Level Shutdown Switch

· DVU Pneumatic Dump Valve

· LS200NDVOR Pneumatic Level Control

· Filter Regulator with Gage

Level Switches

Designed for Harsh Gas Compressor Scrubber Applications; Stainless Steel Float: Specific gravity varies by model and configuration; For Separators/Scrubbers rated for up to 2000 psi (13.8 MPa) [138 bar] Working Pressure; Electric and Pneumatic Models Available.

Dump Valve Operator/ Dump Valve

Hex Union Allows Plug and Seat Replacement Without Piping Removal; Operates on 30–70 psi (207–483 kPa) [2.07–4.83 bar] Control Pressure; Manual Valve Operator.

Sales Bulletin: Scrubber Level Control System

04005 (00-02-0562) rev. 2017/09/11

The LR500 Series Level Regulators automatically add oil to a lubricator to maintain the factory-recommended level. This function eliminates the work time necessary for manual checks and refills. Each model has a low-level shut-down switch to protect equipment when oil supply is lost. If the lubricator oil level drops below the minimum operations level, the low-level switch will operate an alarm and/or shut down the equipment.

Model LR579 is for Lincoln lubricators. It features an adjustable low-level shut-down contact.

LR589 is for Lincoln lubricators, and the LR589NC is the normally closed-wired version of the LR589.

Sales Bulletin: LR500 Series

96121 rev. 2014/10/25

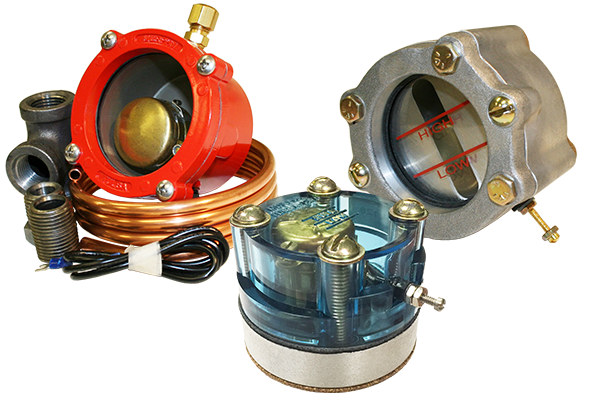

The Float Actuated Oil Level Swichgage instruments are a combination oil level sight gage and adjustable, low and/or high limit switch. The limit switches are normally open during operation — yet closed if the level drops (or rises) to where the float contacts the limit screw. The contact completes a circuit to ground a magneto or trip a Murphy magnetic switch. The magnetic switch can be used to activate alarms and/ or shut down. Models are also available without limit switches.

The level instruments can be used on a variety of crankcases, pump gearcases or oil reservoirs — primarily on small engines and pumps.

Installation is simple, and these instruments save on reduced downtime and repair costs. The following list displays the model and its typical application:

L100: Small engines and pumps with non-vented crankcase

L100W: Small engines and pumps with vented crankcase

L120: Machined surface on crankcase such as Witte, National-Oilwell/Garland

L127: Machined surface on crankcase, specifically, Fairbanks-Morse ZC Series and Bell Engines

L128: Machined surface on crankcase, specifically, Arrow and Continental Emsco/Climax

Sales Bulletin: L100 Series

0710176 rev. 2015/04/13

Installation Instructions: L100 Series

00-02-0172 rev. 2016/02/25