End Devices

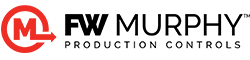

The system provides for liquid control in gas scrubber applications by dumping liquids to drain and protect compressors with with high liquid level switch. Wetted metal parts are made to survive constant use in corrosive environments.

You save money by purchasing the SLS system which includes the following:

· LS200, MLS-020 High Level Shutdown Switch

· DVU Pneumatic Dump Valve

· LS200NDVOR Pneumatic Level Control

· Filter Regulator with Gage

Level Switches

Designed for Harsh Gas Compressor Scrubber Applications; Stainless Steel Float: Specific gravity varies by model and configuration; For Separators/Scrubbers rated for up to 2000 psi (13.8 MPa) [138 bar] Working Pressure; Electric and Pneumatic Models Available.

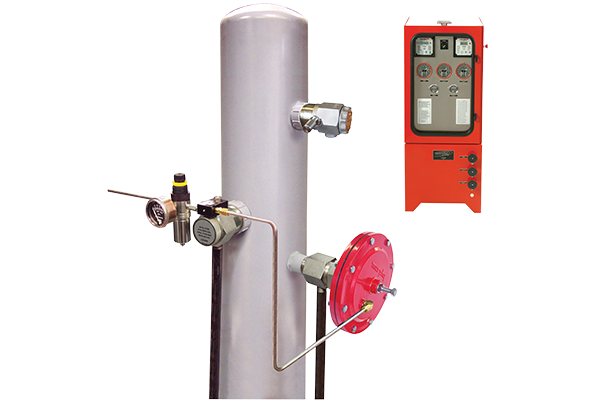

Dump Valve Operator/ Dump Valve

Hex Union Allows Plug and Seat Replacement Without Piping Removal; Operates on 30–70 psi (207–483 kPa) [2.07–4.83 bar] Control Pressure; Manual Valve Operator.

Sales Bulletin: Scrubber Level Control System

04005 (00-02-0562) rev. 2017/09/11

MLS Series Liquid Level Switches are float activated to operate an electrical SPDT reed switch for annunciation/ pilot signal for indication of high level to an annunciator, controller or PLC. The MLS connects directly into the gas scrubber wall and can be used with an FW Murphy weld collar or FW Murphy external float chamber. The MLS Series is available in both 1 1/2 and 2 in. NPT models and with or without the test button.

The test button tests for float function; the complete mechanism including the magnetic activation of the reed switch; and the wiring from the switch to the control panel.

Features of the MLS Series include:

· Clean magnet design virtually eliminates iron filing accumulation on the magnet

· Seal-free construction

· ANSI/ISA 12.27.01 compliant (Single Seal)

· Optional push button to test functions

· Operates in 0.50 specific gravity or heavier fluids

· Designed for harsh gas compressor scrubber applications

· 304 cast equivalent SS body and 304 SS float

· Rated for 2000 psi (13.8 MPa) [138 bar] working pressure

· Trip on rising and falling without need to rotate body

· Electric model only available

· All models screw directly into the scrubber or can be mounted via an FW Murphy External Float Chamber

· CSA C/US Class I, Div. 1, Grp. B, C & D locations

· Canadian registered

Sales Bulletin: MLS Series

1010629 rev. 2017/09/05

Installation & Operations Manual: MLS Series

00-02-0730 rev. 2017/09/05

Test Button Bulletin: MLS TF Model Only

1110827 rev. 2017/09/07

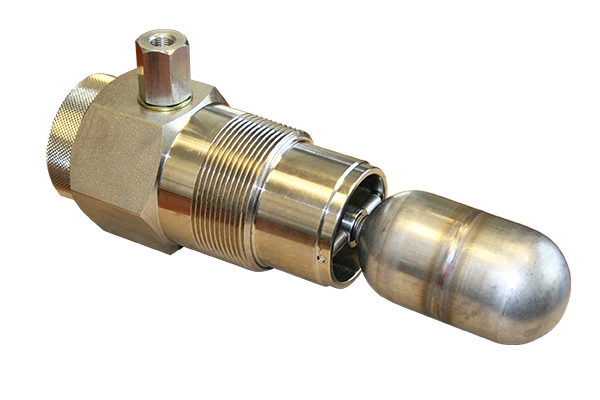

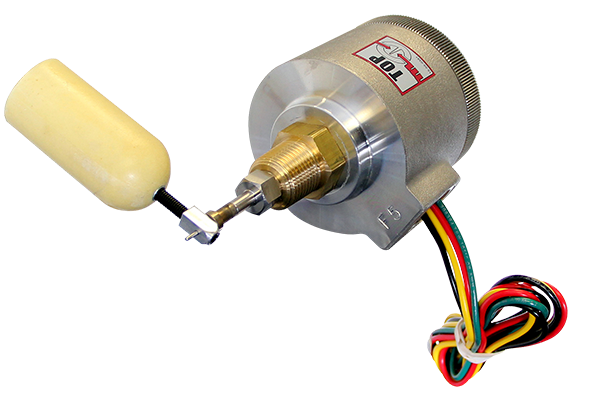

Designed for harsh gas compressor scrubber applications, the LS200 Series Liquid Level Switches feature a robust design that trips on rising liquid level only. With both electric and pneumatic models available, the instruments screw directly into the vessel or can be mounted via an external float chamber. The nickel-plated body provides enhanced corrosion protection while the 304 stainless steel float operates in 0.55 specific gravity and heavier fluids.

The LS200 Series replaces the Murphy Series L1200 Liquid Level Switches. The MSLS (Scrubber Level System) replaces the LS200 high-level shut-down switch with the MLS-020 magnetic level switch.

Additional features include:

· Rated for 2000 psi (13.8 MPa) [138 bar] working pressure

· Listed for Class I, Div. 1, Grp. C & D locations

· Canadian registered

· Stainless steel models available for corrosive atmospheres

Sales Bulletin: LS200 Series

0600009 rev. 2015/09/25

Installation & Operations Manual: LS200 Series

00-02-0671 rev. 2016/04/14

The OPLHC/OPLHACS Series Level Swichgage instruments are combination level-indicating gages with adjustable low- and high-limit switches. Limit switches can be wired directly to electric pilot circuits to operate alarms, shut down or start/stop pumps to maintain predetermined levels.

Surface-mount or panel-mount enclosures are available for both model series. All models feature a 4-1/2 in. (114 mm) dial for easy viewing. Adjustable limit switches are accessible from the front of the Swichgage instrument. Specialized models are available for specific applications involving engines or electric motors.

OPLHC/OPLHACS Series Swichgage instruments include two adjustable, pilot duty, pointer type contacts. Contacts have self-cleaning motion to enhance electrical continuity. Models are available with a rugged bourdon tube or a 316 stainless steel bellows sensing element for greater accuracy and sensitivity in lower ranges.

OPLHBP/OPLHABPS Internal latching control relays are available to provide ON/OFF automation for electric motor applications.

OPLHC and OPLHACS series are available in indication only MurphyGage models (OPLHAGS).

Sales Bulletin: OPLH/OPLHACS Series

94122 rev. 2016/11/03

Installation Instructions: OPLH/OPLHACS Series

00-02-0178 rev. 2012/06/21

The L129 Series Lube Level Swichgage instrument is a combination lube level indicating gage and adjustable low and high limit switches. It provides protection against low oil level or high level caused by overfill or fuel or water seepage into the crankcase. A 6-3/4 inch (171 mm) deep sight gage allows you to check the condition and level of your oil without shutting down the equipment.

Fingertip adjustable limit contacts, through 4-7/8 inch (122 mm) range, make it simple to set high and low limit contacts. If the float touches the high or low limit contact, a normally open circuit will be completed which can activate alarms and/or shut down the equipment.

There are two models in the L129 Series: L129 and L129CK1. The L129 model is designed for grounded, low voltage electrical systems. It features a one-wire-to-ground electrical circuit. The L129CK1 was designed for applications requiring a three-wire, above ground electrical circuit. It features ungrounded contacts and a conduit hub to protect electrical wiring. Options are available for both models.

Sales Bulletin: L129 Series

6572 rev. 2014/10/25

Installation Instructions: L129 Series

00-02-0174 rev. 2012/06/04

The L150 Series Level Swichgage instrument is a combination liquid level gage and low-limit switch; each unit includes (1) a chamber with pivotal float, (2) an indicating dial with pointer and (3) a low-level contact. When properly installed and maintained, the float operates the pointer which, in turn, both indicates level during normal operation and closes a switching circuit if the level falls to the low-limit set point.

The primary use of the L150/EL150K1 is for engine cooling systems, surge or expansion tanks, condenser radiator or vapor phase systems, pressurized or atmospheric systems. The Level Swichgage instrument can also be used to monitor lube oil, hydraulic fluid or diesel fuel reservoirs and activates alarms and/or shut down at a predetermined minimum level. These instruments are built for low pressure systems with a maximum of 25 psi (172 kPa) [1.72 bar].

Sales Bulletin: L150/EL150K1 Series

00072 rev. 2016/08/24

Installation Instructions: L150/EL150K1 Series

00-02-0171 rev. 2014/03/04

Installation Instructions: EL150EX Switch/Terminal Kit

04033N (00-02-0564) rev. 2004/02

Installation Instructions: EL150K1 Visor Kit (15-70-0854)

00-02-0825 rev. 2004/12/02

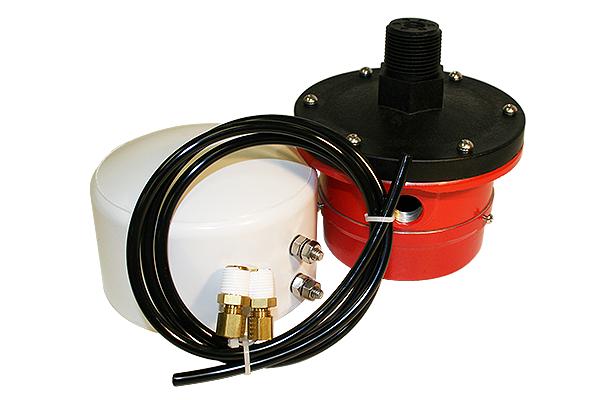

The BLSK1 Bilge Level Switch System operates bilge pumps or alarms. The kit includes all items and fittings necessary to install in your bilge. You order only the parts you want, and you provide brackets, tubing and mounting hardware. Using the proven Air Cell actuating system, all moving parts and switching are remote from bilge liquids and are not affected by corrosion, rust, etc. All wetted parts are of non-corrosive materials.

As bilge level rises, a column of air is captured in the MAC1 Air Volume Cell. The rising bilge level compresses the column of air creating pressure against the large diaphragm in the BLS1 Bilge Level Switch and the switch trips. Switch set point is adjustable. The switch resets as the bilge is pumped out and the air cell recharges itself during normal operation.

The BLS1 is constructed of materials not affected by marine atmospheres: aluminum or bronze body and cover, Buna-N diaphragm.

Sales Bulletin: BLSK1 Series

95107 rev. 2015/09/23

The DF series are diaphragm-operated hydrostatic head pressure level switches. A pressure sensitive diaphragm operates a snap-switch that can be wired directly to electric pilot circuits to control pumps at predetermined levels. Typical application is to start and stop electric driven pump(s) to maintain tank levels. It is also applicable to engine-driven pumps.

The nitrile sensing diaphragm is impervious to most liquids and is sensitive enough to control levels with 1/4 in. (6 mm) repeatability. See model descriptions for limits of switch trip point adjustability. Materials include aluminum body, glass-filled nylon bottom plate and a special alloy leaf snap switch as standard.

This simple level switch is highly reliable and can be worked into almost any new or existing system without major modification or special tools.DF755 and DF757 are suitable for atmospheric tanks in a non-hazardous area. The SPDT snap-switch for the DF755 is preset for a 4 in. (102 mm) differential in liquid level. The DF757 trip point is adjustable over a 108 in. (2743 mm) differential.

Sales Bulletin: DF Series

94124 rev. 2016/03/02

Installation & Operations Manual: DF Series

00-02-0831 rev. 2016/02/29

The Murphy L971 Series Level Switch detects low oil level in a compressor’s crankcase. As oil level in the crankcase depletes, the float on the L971 switch falls, and when reaching the predetermined limit, it will trip the internal snap-switch sounding an alarm or initiating shutdown.

The L971 is designed for Ingersoll-Rand Type 30, Type 40 and ESH compressors, yet it can be adapted to fit other compressors that have an inspection plate extending below normal operating oil level. It installs with minimal downtime and has a two-year limited warranty.

The L971 has a 1/2 NPT process connection and features an explosion-proof enclosure, durable SPDT snap-switch and rigid polyurethane foam float. A 304 stainless steel float is available on certain configurations.

Sales Bulletin: L971 Series

7229 rev. 2014/10/25

Installation Instructions: L971 Series

L94071N (00-02-0173) rev. 2014/11/19