Miratech Catalyst Applications

Whether you are meeting mandated air quality standards, designing a new installation or preparing to retrofit an existing one, we'll introduce a broad range of advanced catalytic processes to meet your needs. Once the correct process is identified, we'll focus on developing an efficient, innovative and cost-effective solution for your specific catalytic application.

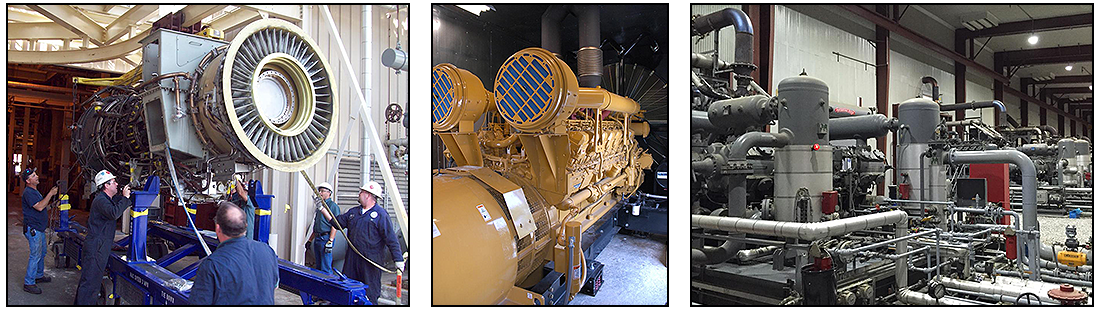

Stationary Internal Combustion Engines (I.C.E.)

Stationary Internal Combustion Engines (ICE), also known as both rich and lean burn reciprocating engines, are widely used to generate electric power and compress natural gas throughout North America. There are several million stationary reciprocating engines in use throughout the United States.

Rich-Burn:

For rich burn, or stoichiometric engines, Miratech is the leader in the design and production of high performance Non-Selective Catalytic Reduction (NSCR) catalyst and systems for stationary applications.

Lean-Burn:

For lean burn engines, burning either diesel or natural gas, Miratech manufactures a robust oxidation catalyst for 4-cycle and 2-cycle applications.

Miratech manufactures a full line of housings, silencers and catalyst elements for all sizes and brands of stationary reciprocating engines. All products and solutions meet the strictest environmental regulations including NESHAP.

Gas Turbines Oxidation Catalyst

Miratech's Advanced Catalytic Technology (ADCAT) CO/VOC oxidation catalyst are custom manufactured to your specifications to yield optimal conversion efficiencies for the lowest evaluated or life cycle cost for all turbine types: new, replacement and retrofit.

Heavy Duty-Stainless Steel Catalyst Element Construction:

· Bonded discrete cell density. Bonded discrete cell substrate

· Highest catalytic surface area (<40% more than herringbone) yielding the lowest possible pressure loss

· Prevents substrate nesting, blow-outs and exhaust bypass

· 5 -10 year mechanical integrity guarantee

Gas-Fired Industrial Boilers

Operators of gas-fired industrial boilers are continually looking at advanced technologies to meet their emission control goals. With increasing regularity, answers are found in the catalytic systems designed and manufactured by Miratech.

Industrial boilers are often installed in "non-attainment" areas. Non-attainment areas are regions within the country where the concentration of one or more criteria pollutants exceeds the level set as the federal air quality standards. Once the EPA announces that an area does not meet the health standard, the State works with businesses, local governments, and the public to reduce the emissions from sources contributing to the nonattainment status of the area. Hence, these boilers must incorporate proven oxidation catalyst technology to reduce CO and VOC emissions.

The EPA has finalized the Boiler Maximum Achievable Control Technology (MACT) Rule. The rule is intended to control emissions of hazardous air pollutants (HAP's) from industrial, commercial, and institutional boilers and process heaters. Fortunately, Miratech has products and solutions that meet current and future Boiler MACT regulations. It all starts with proprietary design and construction from the ground up.